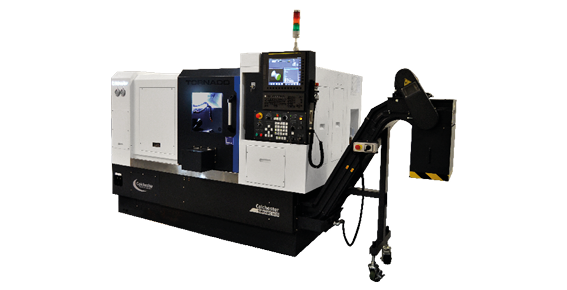

Are you looking to enhance your production capabilities with state-of-the-art CNC machinery? Look no further! Our Tornado slant bed production CNC lathes are engineered to deliver unparalleled precision, efficiency, and reliability.

Available in 2-axis and 3-axis (MillTurn) configurations and suited to all sectors of engineering, manufacturing and education, Tornado offers exceptional return on investment. All machines are highly rigid in construction and utilise linear guideway technology for fast, precise and smooth machining, compact in footprint and ergonomically designed for operator use and comfort.

Why Choose Slant Bed CNC Lathes?

1. Optimized Chip Removal: The slant bed design facilitates seamless chip removal, ensuring uninterrupted machining operations and superior surface finishes.

2. Enhanced Rigidity: Our machines feature a robust slant bed structure, providing exceptional stability and vibration damping for precision machining of complex parts.

3. Improved Accessibility: With easy access to the workpiece and tooling, setup times are reduced, maximizing productivity and minimizing downtime.

4. Versatile Machining Capabilities: From simple turning operations to complex multi-axis machining, our CNC lathes offer versatility to meet the demands of various industries.

All Tornado CNC turning centres come with the latest generation of CNC control system from Fanuc or Siemens. With their user-friendly controls and interfaces, these machines are accessible to a broader range of operators, reducing the learning curve and increase overall efficiency.

All machines have conversational programming integrated into the control system as standard.

Whether it be Fanuc’s Manual Guide I or Siemen’s Shop Turn, CNC conversational programming simplifies the process by providing an intuitive interface for creating machine tool paths. This allows users without extensive G-code knowledge to easily program CNC machines, reducing the learning curve and enabling quicker implementation. It enhances efficiency, minimizes errors, and promotes faster prototyping and production.

Contact Us Today

Take your production capabilities to the next level with our cutting-edge slant bed production CNC lathes. Contact us today to learn more about our products and how we can help streamline your manufacturing processes. Call us on +44 (0) 1924 415 000 or email sales@colchester.co.uk

Need help?

Call our Sales team on 01924 415000